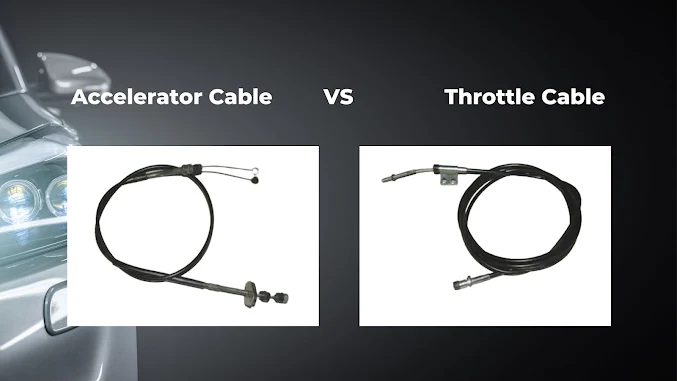

Vehicles are complex that require an in-depth knowledge of their components to ensure optimal performance. The throttle cable and accelerator cable are two such critical components. While they may appear to be the same, they serve unique duties that are critical to the engine's efficient operation.

The accelerator cable links the accelerator pedal to the throttle body. When the pedal is depressed, the cable pulls the throttle open, letting more air into the engine and increasing power output. The throttle cable, on the other hand, controls the opening and closing of the throttle valve. It controls the amount of air that enters the engine, which in turn affects the engine's speed.

II. Throttle Cable: The Basics

A. Definition and Function

The throttle cable is an important part of the engine control system of a vehicle. It acts as a critical link between the accelerator pedal and the throttle body, allowing for more precise control of airflow into the engine. The throttle cable, in essence, governs the vehicle's speed by controlling the amount of air that enters the engine.

When the accelerator pedal is pressed, the cable pulls the throttle open, letting more air into the engine and increasing the vehicle's speed. When the accelerator pedal is depressed, the cable relaxes and the throttle closes, lowering the amount of air that enters the engine and slowing the car. Overall, the throttle cable is critical to a vehicle's operation and performance.

B. Components and Structure

Throttle cables play an important role in the operation of cars and other vehicles. These cables are typically made of robust materials and have inner and exterior layers. The inner cable is in charge of delivering the pushing power from the accelerator pedal to the throttle body of the engine, which regulates the quantity of air and fuel mixture that enters the engine.

Meanwhile, the outer layer protects the inner cable while also guiding it along its course. Without this layer of protection, the inner cable would be vulnerable to harm from the environment or friction with other components. Overall, the throttle cable is critical to the smooth and responsive running of a vehicle's engine.

C. Role in the Engine Control System

The throttle cable, which connects the accelerator pedal to the throttle body, is an important part of the vehicle's control system. It's in charge of relaying the driver's input to the engine, which then turns it into activity. The driver could not regulate the vehicle's speed without the throttle cable.

Throttle cables come in a variety of shapes and sizes, depending on the vehicle's make and model. They can be made of steel, nylon, or plastic. The cable is normally connected at one end to the accelerator pedal and the other end to the throttle body. As the driver depresses the pedal, the cable opens the throttle body, allowing more air into the engine and increasing the vehicle's speed.

III. Accelerator Cable: Unveiling Its Purpose

A. Definition and Role

An accelerator cable, which is frequently confused with the throttle cable, is an important component of a vehicle's engine system. While the throttle cable is in charge of opening and shutting the throttle valve, the accelerator cable is in charge of relaying the driver's directions to the throttle and modifying the engine's speed accordingly. This cable is in charge of regulating the amount of air and fuel that enters the engine, which controls the RPM (revolutions per minute) of the engine.

Accelerator cables are normally constructed of steel wire and is attached at one end to the accelerator pedal and at the other to the throttle body. It is critical to inspect and maintain the accelerator cable on a regular basis to ensure that it is working properly and efficiently, as problems with the cable can result in decreased engine performance and even unsafe driving conditions.

B. Components and Design

An accelerator cable, like the throttle cable, is made up of two parts: the inner cable and the outside casing. The inner cable is an active component that connects to the throttle linkage. As the driver depresses the accelerator pedal, the inner cable pushes against the spring tension inside the throttle body, opening the throttle valve and letting more air into the engine.

The outer casing, on the other hand, provides protection and support for the inner cable. It protects the cable from dirt, debris, and moisture that could cause corrosion or damage to the cable, ensuring that it remains in good working order.

C. Interaction with the Throttle Mechanism

The accelerator cable is a critical component in the operation of any vehicle. Its function is to ensure a responsive and smooth interaction between the driver's foot movements and the engine's throttle. When the driver presses the accelerator pedal, the action is transmitted to the throttle body, enabling more air and fuel into the engine. As a result, the engine's speed and power rise. The driver would be unable to manage the vehicle's acceleration without the accelerator cord, making it difficult to drive safely and effectively. To avoid potential road safety problems, ensure that the accelerator cable is frequently maintained and, if necessary, replaced.

IV. Key Differences

A. Operational Dissimilarities

While each of these cables contribute to the acceleration process, they each have a unique purpose. The throttle cable is in charge of directing the airflow into the engine, whereas the accelerator cable is directly related to the throttle position.

The throttle cable controls the volume of air that enters the engine, while the accelerator cable controls how far the throttle opens to allow that air in. This sophisticated mechanism guarantees that the engine receives the proper amount of air and fuel to work efficiently and effectively.

B. Material Variations

To ensure optimal durability, throttle cables are frequently strengthened with metal. The metal reinforcement adds strength to the cable, allowing it to endure the continual tension, pressure, and abrasion that it experiences during typical vehicle use. This strengthening also keeps the wire from stretching or breaking, which might pose major safety risks.

Accelerator cables may be designed to be more adaptable to the specific needs of their purpose. Accelerator cables, unlike throttle cables, may not require as much reinforcing because they are not subjected to the same level of consistent tension or pressure. They must, however, be sturdy enough to resist the wear and tear that comes with constant use.

C. Impact on Vehicle Performance

It is pivotal to understand the disparities between these two cables, as a malfunction in either can cause specific performance problems. A defective throttle cable can result in slow acceleration, whereas an accelerator cable issue can lead to an unresponsive throttle control.

V. Maintenance and Troubleshooting

A. Throttle Cable Maintenance Tips

Regular maintenance and visual checks are required to ensure the longevity and effective operation of the throttle cable. These precautions can aid in the early detection of indicators of wear or fraying, preventing unexpected failures that could lead to accidents or costly repairs.

During a visual inspection, look for signs of fraying, kinking, or damage to the cable. It is also critical to inspect the cable routing and ensure that it is correctly secured and not rubbing against any other components. Lubrication should be done in accordance with the manufacturer's instructions.

B. Accelerator Cable Care and Common Issues

One common problem with accelerator cables is the buildup of debris over time, which can cause stiffness and hinder the ease of acceleration. To avoid this problem, it is critical to inspect and clean the cable on a regular basis.

Another typical problem is cable slack, which can impair vehicle responsiveness. It is critical to keep the cable appropriately set in order to retain peak performance. Drivers may ensure a smooth and responsive driving experience by keeping the accelerator cable clean and correctly adjusted.

C. Importance of Regular Checks

Routine checks of the Accelerator Cable and Throttle Cable are essential for a trouble-free driving experience.

It is recommended to inspect the cables for symptoms of wear, such as fraying or corrosion, as well as any looseness or stiffness.

By inspecting these cables on a regular basis, you may help to ensure a safe and dependable driving experience.

VII. Choosing the Right Cable

There are a few crucial variables to consider when selecting the correct accelerator and throttle cable for your car. First and foremost, be certain that the cable you select is the proper length for your exact make and model. This is critical to ensuring good operation and avoiding any safety concerns.

Another significant factor to consider is the cable's substance. Many cables are made of braided steel, which is very strong and long-lasting. However, some contemporary cables are created from synthetic materials that can provide increased flexibility and corrosion resistance.

You should also consider the cable's attachment type, which can differ based on the make and model of your car. Some cables are designed to bolt directly to the engine, while others may require the installation of additional brackets or adapters.

Comments

Post a Comment